Environment & Energy

Related: About this forumAutonomous hydrogen-powered mining truck achieves test successes in China

Autonomous hydrogen-powered mining truck achieves test successes in China

im-mining.com | 11/18/2024

The latest rigid truck project to get off the ground is at CHN Energy’s Shenhua Beidian Shengli Energy Co Ltd, better known as the Shengli mine, in Xilinhot, Inner Mongolia, where a 110 ton class truck known as the HT3100E built by Aerospace Heavy Industry (AHI), part of China Space Sanjiang Group (CSSG), is now in test operation. This FCEV uses hydrogen fuel cells supplied by Reshape Energy.

It is equipped with a 70MPa hydrogen storage system and the truck can reach a maximum speed of 50 km/h under heavy load conditions. Reshape Energy says its independently developed fuel cell system has the advantages of strong load capacity, long service life, and high safety. The average operating altitude is about 1,000 m at Shengli with a big temperature difference between winter and summer ranging from -25°C to 30°C. Reshape Energy cooperated with AHI to improve the vibration resistance and heat dissipation performance of the fuel cell system. The truck can reduce diesel consumption of 320,000L per year equating to over 230 tons of carbon emissions.

Not only that but the truck is being operated autonomously – one of the first if not the first FCEV to do so – using autonomous haulage technology supplied by one of China’s AHS leaders, TAGE Idriver. The hydrogen fuel cell driverless heavy-duty mining dump truck project was included in the ‘1025’ project of the State-owned Assets Supervision and Administration Commission (SASAC) of the State Council. Currently, the hydrogen energy mining truck has achieved full-load trial operation and has been run autonomously for over 600 km.

The truck has a total hydrogen storage capacity of 5,052 litres with a system weight of 203 kg and combines four 140 kW hydrogen fuel cell modules with a lithium iron phosphate battery for total power output of 900 kW. Liu Xi, Director of the Shengli Energy Mechanical and Electrical Information Center says of the truck project: “This is to adapt to the special working environment of the northern open-pit coal mines, which have long winters and mostly extremely cold weather. Hydrogen fuel cells are used in extreme climates such as extreme cold and wind and snow in the north. It can continuously provide heat under certain conditions, and at the same time only generate water during driving. It can also work continuously for a long time, enabling high-intensity operations of more than 20 hours a day in mines.” full:

https://im-mining.com/2024/11/18/autonomous-hydrogen-powered-mining-truck-achieves-test-successes-in-china/

Where are they going to get the hydrogen?

Aug 31, 2023: China's First Mega-Watt Solar PV-Powered Green Hydrogen Project Achieves Full Production

https://www.jingsun-power.com/news/china-s-first-mega-watt-solar-pv-powered-green-70566251.html

Think. Again.

(17,901 posts)...and THAT is some VERY heavy equipment!

Caribbeans

(975 posts)That's ~80-90 kWh. A Cybertruck battery weighs ~721 kg.

If this mining truck is 10x the (ridiculous) Cybertruck battery that's a lot of weight.

And talk about efficiency? That weight must be carried around everywhere the truck goes.

And it might last 10 years and then you need a new one.

"Batteries Batteries Everywhere" is not a sustainable - or green - solution to anything

Think. Again.

(17,901 posts)We are going to need the full spectrum of green energy technology to cut back CO2, and each different type of green tech has it's own best uses.

Windy Apple

(23 posts)There are zero batteries. The hydrogen is the battery. That’s where the energy is stored: in the hydrogen.

The propulsion is from heat.

Read up

OKIsItJustMe

(20,731 posts)They are a hybrid system, the fuel cells charge the batteries, instead of having an internal combustion engine charging them. This vehicle is no exception.

eppur_se_muova

(37,388 posts)The heat is a byproduct of direct electricity production, and most current fuel cells operate at elevated temperatures.

Fuel cells are basically flow-through batteries -- the chemicals that store energy are continuously replaced, unlike a normal sealed battery. The battery in this vehicle is probably necessary for initial operation, while the fuel cell warms up. In effect, it's a hybrid vehicle, and we should expect most fuel cell vehicles to operate the same way. The fuel supplies the energy long-term, the battery keeps things running while the fuel cell warms up short-term, then the fuel cell recharges the battery. Like current hybrid vehicles, with fuel cells substituted for internal combustion engines.

OKIsItJustMe

(20,731 posts)(Please note: US Department of Energy Publication. — Copyright concerns are nil.)

https://afdc.energy.gov/vehicles/how-do-fuel-cell-electric-cars-work

Like all-electric vehicles, fuel cell electric vehicles (FCEVs) use electricity to power an electric motor. In contrast to other electric vehicles, FCEVs produce electricity using a fuel cell powered by hydrogen, rather than drawing electricity from only a battery. During the vehicle design process, the vehicle manufacturer defines the power of the vehicle by the size of the electric motor(s) that receives electric power from the appropriately sized fuel cell and battery combination. Although automakers could design an FCEV with plug-in capabilities to charge the battery, most FCEVs today use the battery for recapturing braking energy, providing extra power during short acceleration events, and to smooth out the power delivered from the fuel cell with the option to idle or turn off the fuel cell during low power needs. The amount of energy stored onboard is determined by the size of the hydrogen fuel tank. This is different from an all-electric vehicle, where the amount of power and energy available are both closely related to the battery's size. Learn more about fuel cell electric vehicles.

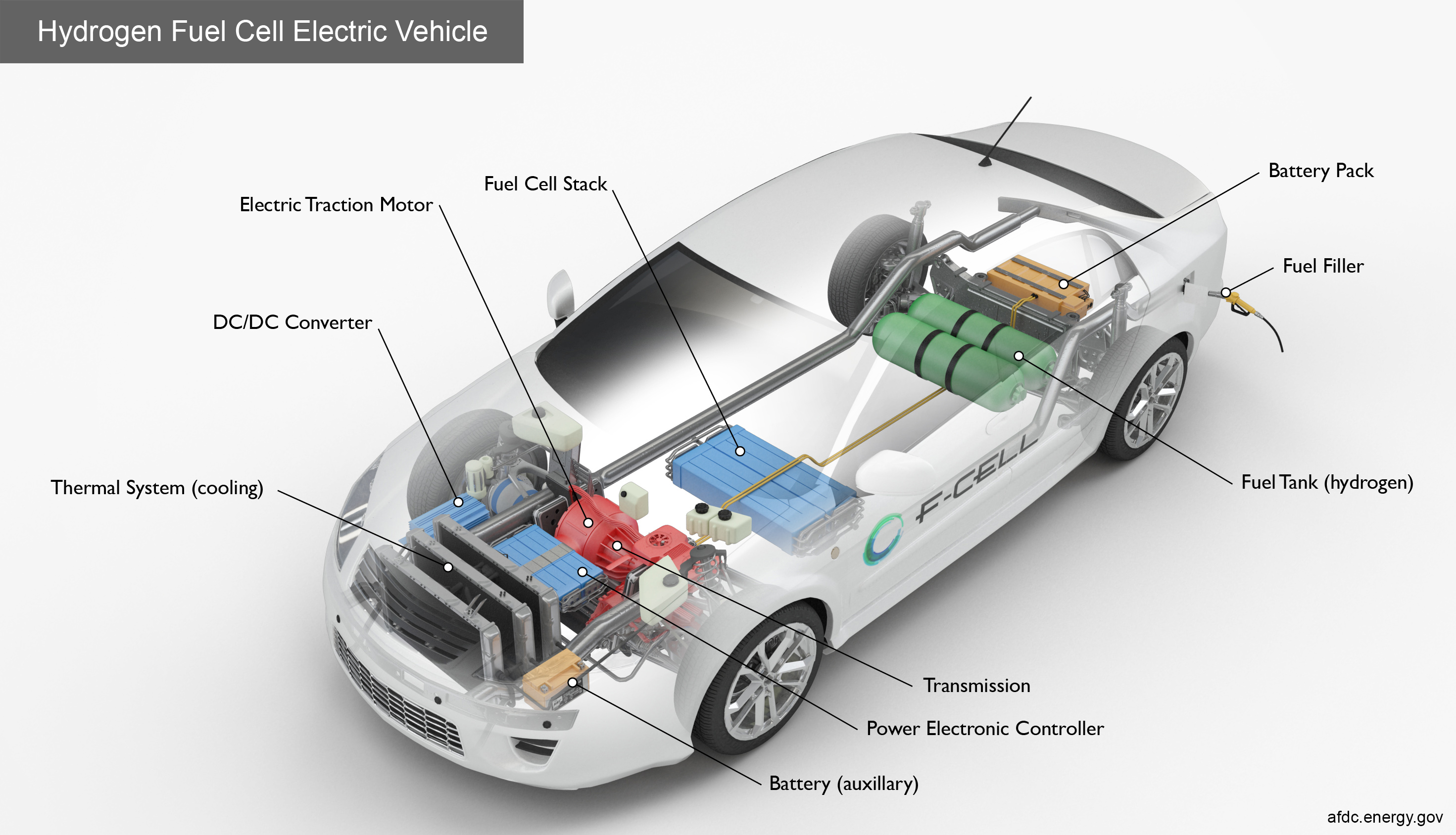

Key Components of a Hydrogen Fuel Cell Electric Car

Battery (auxiliary): In an electric drive vehicle, the low-voltage auxiliary battery provides electricity to start the car before the traction battery is engaged; it also powers vehicle accessories.

Battery pack: This high-voltage battery stores energy generated from regenerative braking and provides supplemental power to the electric traction motor.

DC/DC converter: This device converts higher-voltage DC power from the traction battery pack to the lower-voltage DC power needed to run vehicle accessories and recharge the auxiliary battery.

Electric traction motor (FCEV): Using power from the fuel cell and the traction battery pack, this motor drives the vehicle's wheels. Some vehicles use motor generators that perform both the drive and regeneration functions.

Fuel cell stack: An assembly of individual membrane electrodes that use hydrogen and oxygen to produce electricity.

Fuel filler: A nozzle from a fuel dispenser attaches to the receptacle on the vehicle to fill the tank.

Fuel tank (hydrogen): Stores hydrogen gas onboard the vehicle until it's needed by the fuel cell.

Power electronics controller (FCEV): This unit manages the flow of electrical energy delivered by the fuel cell and the traction battery, controlling the speed of the electric traction motor and the torque it produces.

Thermal system (cooling) - (FCEV): This system maintains a proper operating temperature range of the fuel cell, electric motor, power electronics, and other components.

Transmission (electric): The transmission transfers mechanical power from the electric traction motor to drive the wheels.