'Montana Masks' pop up all over the world, move from 3D printers to injection molds [View all]

'Montana Masks' pop up all over the world, move from 3D printers to injection molds

By ROB ROGERS Mar 31, 2020 Updated 1 hr ago

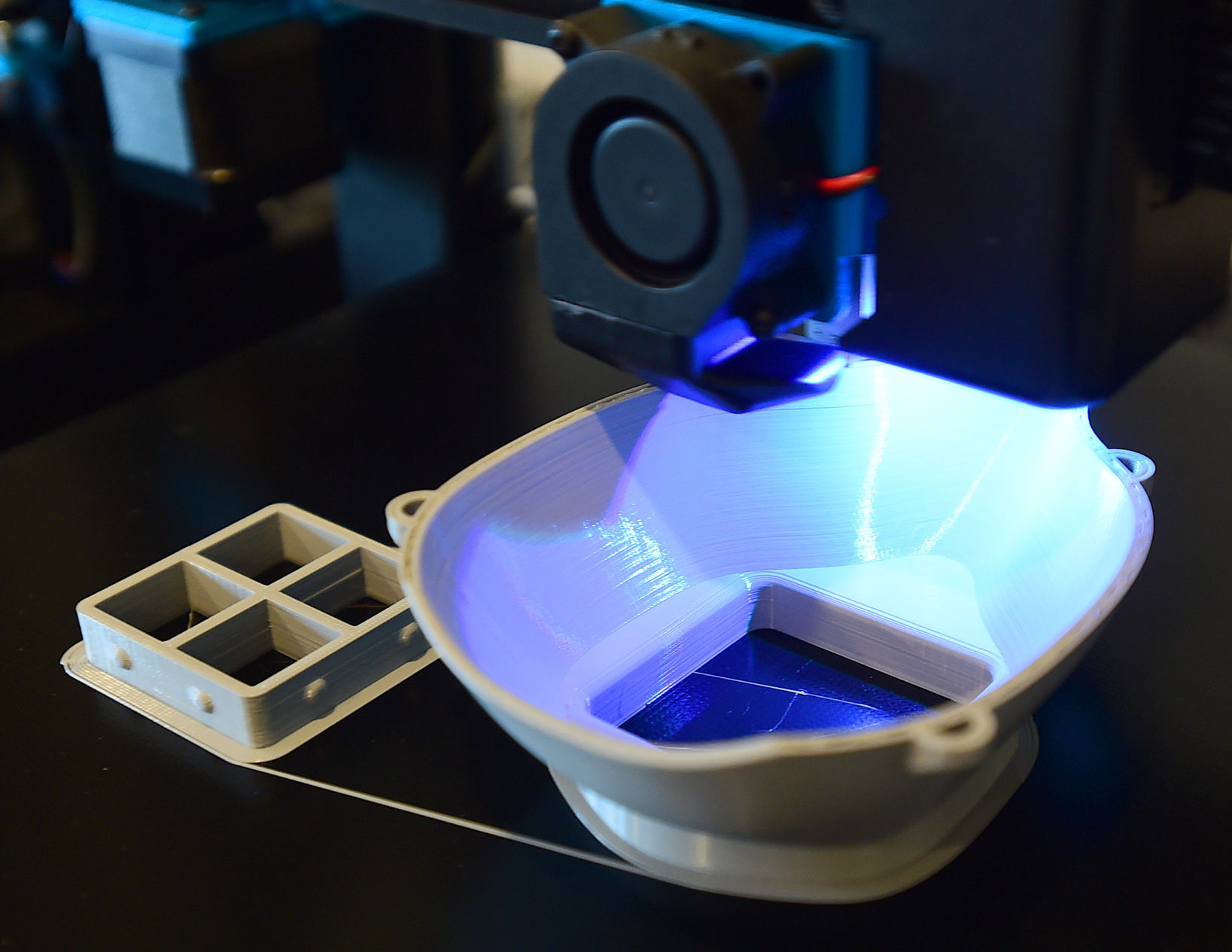

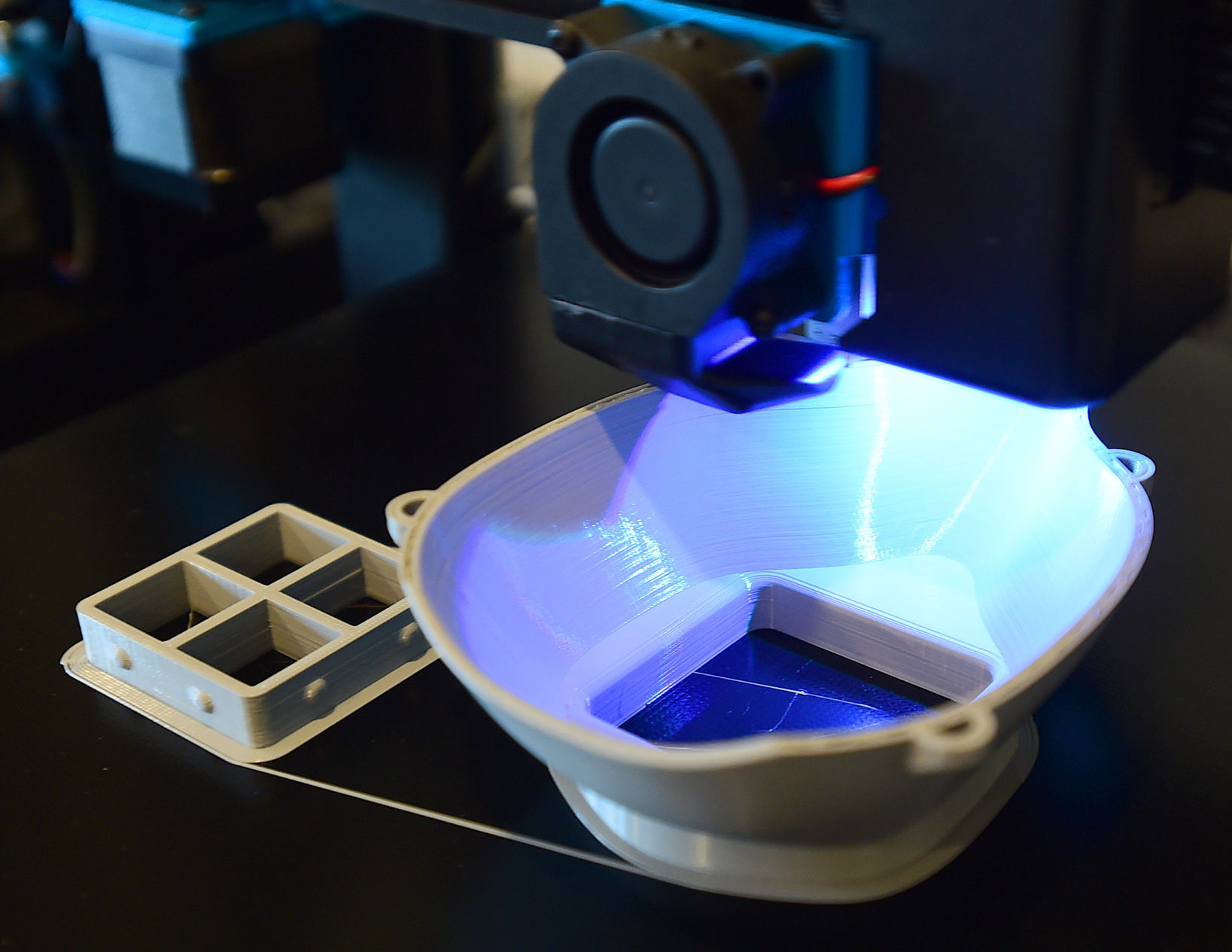

Colton and Spencer Zaugg, along with Dr. Dusty Richardson, have designed a face mask using a replaceable filter they are making on a 3D printer.

LARRY MAYER, Billings Gazette

The reusable

plastic face masks designed for 3D printers by a college graduate and a pair of local medical professionals have gone global. The free open-source software file they created has been downloaded or shared in 148 countries across six continents.

Dubbed the

Montana Mask, the design has now made the jump from 3D printers to injection mold production, crafted by the Bozeman company Spark R&D.

That move allows for much faster mass production and gives the masks a more comfortable feel. Injection mold production can use materials that are softer and more flexible than the plastic required by 3D printers.

{snip}

Spark R&D

designs and produces splitboard bindings and accessories. Splitboards are backcountry snowboards that can separate into skis. Its Bozeman shop houses design and production equipment and is able to craft and produce all the parts and pieces it needs for its product line.

{snip}

To make the mask design more accessible, they've uploaded everything — including testing results and their research and development — to a new website,

www.makethemasks.com.

Billings 'tinkerers' design reusable face mask for local battle against coronavirus